Thống kê

| 3855937 | |

| Số người đang online | 8 |

| Số truy cập hôm nay | 844 |

| Số truy cập tháng này | 43148 |

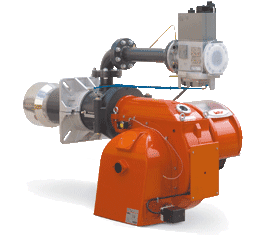

Serie BGN LX

Technical and functional features

- Low NOx and CO gas-fired burners, EN676 "Classe III".

- Two-stage progressive output operation.

- Ability to operate with output modulation by means of automatic RWF40 regulator mounted on the control panel (order separately with the specific modulation kit).

- Compatible with any type of combustion chamber.

- Air-gas mixing at blast-pipe.

- Burnt gas recycling blast-pipe able to achieve very low pollutant emissions, particularly with regard to nitrous oxides (NOx).

- Ability to obtain optimal combustion values by regulating combustion air and blast-pipe.

- Maintenance facilitated by the fact that the mixing unit can be removed without having to remove the burner from the boiler.

- Minimum and maximum air flow regulation for first and second stage by means of electric servomotor with pause closure of gate to prevent any heat dispersion to flue.

- Fan speed adjustment in relation to changes in burner demand provided by means of inverter, to obtain a significant reduction in noise levels and electricity consumption (version V only).

- Tightness gas valve control, EN676.

- Comes with 1 flange and 1 insulating seal to connect the burner to the application.

Design features

- Light aluminium alloy fan part.

- High performance centrifugal fan.

- Combustion air inlet with device to adjust the air flow.

- Sliding boiler coupling flange to adapt the head protrusion to the various types of boilers.

- Adjustable blast-pipe with stainless steel nozzle and deflector disk in steel.

- Three-phase electric motor to run fan (controlled electronically by means of a motor speed controller in "V" execution).

- Air pressure switch to ensure the presence of combustion air.

- Monoblock modulating gas train complete with operation and safety valve, valves seal control, minimum pressure switch, pressure regulator and gas filter.

- Sequence controller - EN 298..

- Flame scanning by ionisation electrode.

- Control panel comprising stop/go switch, automatic/manual and minimum/maximum selector, operation and block indicator.

- Terminal block for the electrical and thermostatic connections to the burner and to control the second stage of working or for the connection of the electronic output regolator.

- Electrical plant protection rating IP40.

| Code | Name | Minimum capacity (kW) | Maximum capacity (kW) |

|---|---|---|---|

| 15270010 | BGN 300 LX 50Hz | 657.00 | 2982.00 |

| 15270015 | BGN 300 LX V 50Hz | 657.00 | 2982.00 |

| 15290010 | BGN 390 LX 50Hz | 400.00 | 3950.00 |

| 15290015 | BGN 390 LX V 50Hz | 400.00 | 3950.00 |